Injection adhesive packer KP50KN

Graduated prices

| Quantity | Discount (%) | Price |

|---|---|---|

| 10 | - | 0,61 € |

| 100 | 5 % | 0,58 € |

| 1.000 | 8 % | 0,56 € |

| 2.000+ | 10 % | 0,55 € |

0,61 €

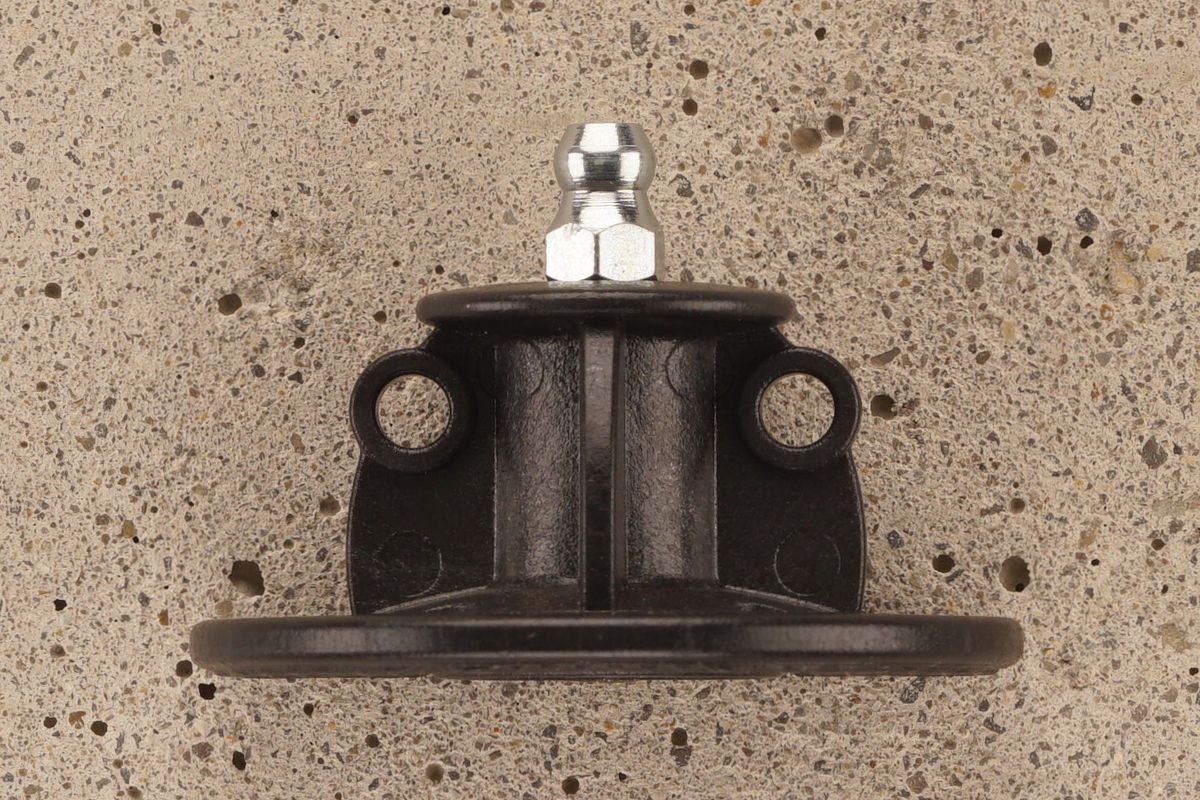

Injection- Adhesive packer KP50KN - Plastic adhesive packer (glass fiber reinforced) for crack injection.

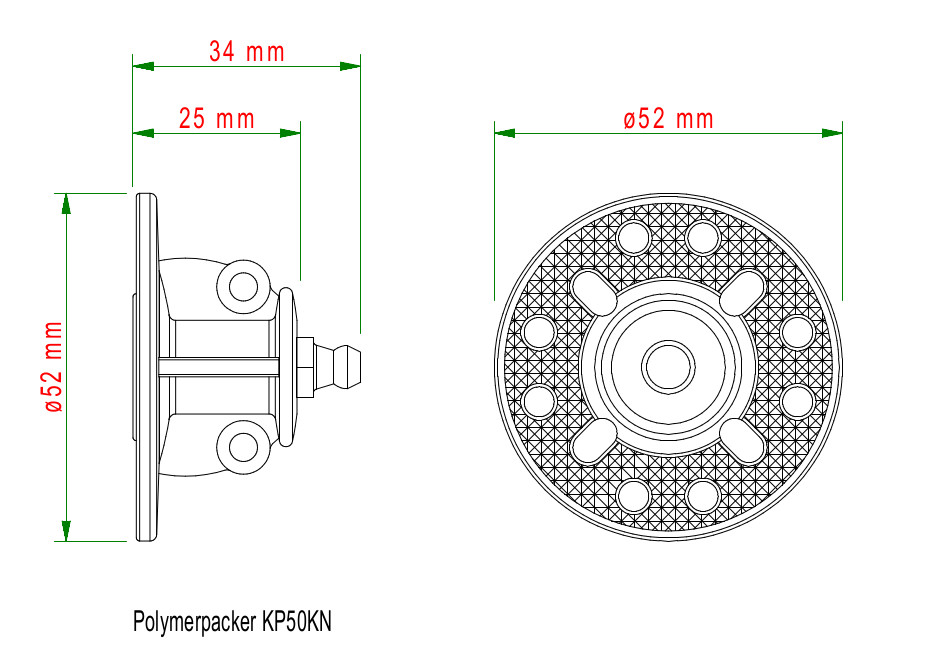

Made of glass fiber reinforced plastic - very robust, adhesive surface Ø 50 mm.

Connection: screwed-in steel conical nipple DIN 71412 with check valve. Opening pressure approx. 10 bar.

Availability: 2270 in stock

Injection adhesive packer KP50KN

for bonding to surfaces of construction elements in which drilling holes for crack injection is not desired or not permitted (ZTV-RIS).

Examples of use: Crack injection on structural elements made of prestressed concrete, concrete with dense reinforcement, or exposed concrete elements. Suitable for injection of epoxy resin, polyurethane resin, polyester resin.

Polymerpacker Injection adhesive packer

- Made of a very adhesive high-performance plastic.

- Adhesive surface equipped with a surface structure optimized for bonding.

- Can be used for maximum injection pressures of up to 60 bar when gluing with high-quality adhesives to solid surfaces.

Polymerpacker Injection adhesive packer. The original, millionfold proven product, produced by us since 1993.

Crack injection according to ZTV-RIS on a concrete construction element, st's so easy:

1. clean crack by sandblasting or wire brushing and dry with hot air if necessary.

2. to prepare injection channels, drive steel nails at least approx. 5 mm deep into the crack at intervals of approx. 20 cm.

Apply suitable adhesive to the bonding surface of the adhesive packers and press the adhesive packers over the steel nails onto the surface of the concrete component. The adhesive should emerge from the openings on the backs of the bonding surfaces to create the strongest and most secure bond possible. The hammered-in steel nails prevent the injection channels from being blocked by adhesive.

Close the crack with glue, pull out the steel nails after the glue has hardened and screw the tapered nipples into the threaded holes, but do not tighten them yet.

Starting at the beginning of the crack on the first packer, tighten the cone nipple and inject resin until foam-free resin comes out of the second packer between the thread of the packer and the cone nipple. Now also tighten the cone nipple on the second glue packer and inject resin until foam-free resin emerges from the third glue packer between the thread of the glue packer and the cone nipple. Continue in this order until resin has been injected into all the glue packers. Then inject resin again into all the glue packers. This procedure is intended to systematically press out the air in the crack and avoid air pockets.

Our recommendation:

For crack injection use the lowest possible viscosity Use epoxy, polyurethane or polyester resins at a maximum injection pressure of approx. 20 bar. For bonding injection adhesive packers to concrete surfaces, 2-component polyester composite mortar (anchor adhesive) has proved very successful.

You might also like ...

-

Injection packers + pumps

Connection coupling (gripping coupling) for taper nipple

4,34 € Add to shopping cart

Similar products

-

Injection packers + pumps

Injection packer SPS10100 for 10 mm drill hole

1,28 € Add to shopping cart